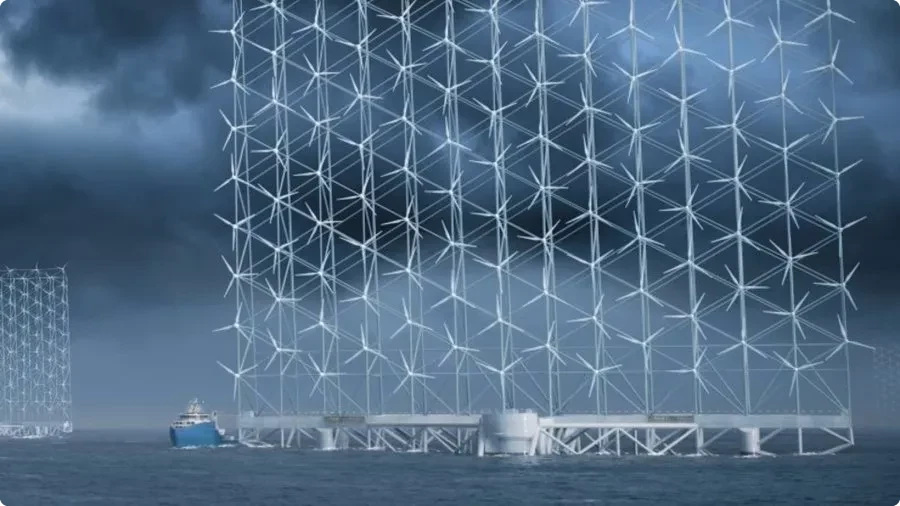

Floating “Wall of Wind Turbines’ Gets Approval

A Norwegian company is developing an innovative wind energy concept called the “Windcatcher,” an offshore floating facility. Instead of using a few giant turbines, the Windcatcher will comprise hundreds of small turbines packed together. This visionary project is spearheaded by Wind Catching Systems (WCS).

The Windcatcher has reached a significant milestone by receiving certification from DNV, a leading global classification agency. This certification confirms the technical feasibility of the design, allowing the project to advance to the next stage.

The Windcatcher concept involves a floating offshore wind farm that uses multiple small 1MW turbines instead of traditional large turbines. These innovative turbines can capture 2.5 times more energy per square meter of wind flow compared to standard three-blade turbine designs. The unique design, resembling a “floating wall of wind,” aims to double energy output.

The company plans for the Windcatcher to generate 40MW of power in the future. In the long term, WCS aims to add units with a capacity of up to 126 MW.

The Windcatcher is designed to withstand the harsh conditions of the open sea. It is a modular system that can be scaled up or down based on energy needs. Each unit connects to a central substation, which transmits the electricity to the grid.

This is a very interesting concept. One of the issues surrounding wind turbines is there tendency to kill large amounts of birds. Hopefully these are big enough for flocks of birds to recognize that they need to go around it.