Flying Hydrogen Taxi

Recently we wrote about both hydrogen power and the new eVTOL flying taxi’s. Now, those two worlds have collided in a fascinating way.

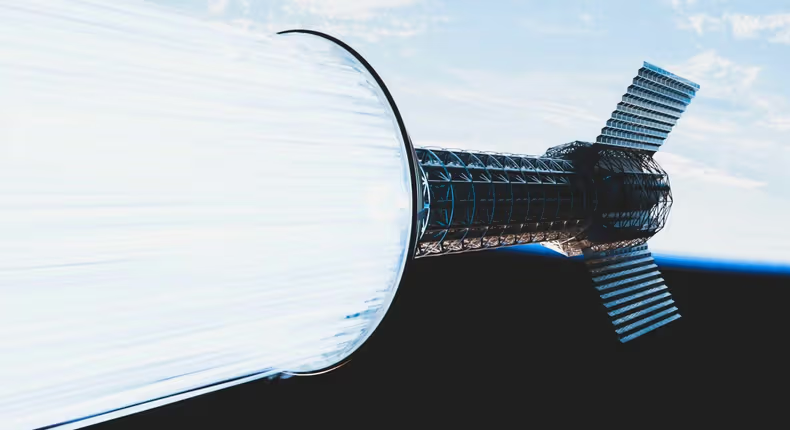

A flying-car-like vertical takeoff aircraft created by Joby Aviation has completed a groundbreaking 523-mile test flight using hydrogen power. The aircraft, which reportedly emitted only water vapor, is being promoted as a more environmentally friendly alternative to traditional gas-powered jets for mid-range, regional travel. Although there are ongoing concerns about the long-term viability of hydrogen power at scale, this test flight demonstrates that it is possible to retrofit existing electric aircraft with hydrogen fuel cells to extend their range effectively.

Joby is among several companies developing air taxi services using vertical takeoff and landing vehicles (VTOLs). Previously, Joby focused on fully electric battery-powered aircraft with a range of about 100 miles, designed for intra-city transport and trips to major airports. For the new test flight, Joby modified a pre-production prototype of its battery-electric aircraft with a liquid hydrogen fuel tank and fuel system. This hydrogen-powered VTOL successfully completed a 523-mile flight above Marina, California, with no in-flight emissions and landed with 10% of its hydrogen fuel remaining.

Related: Flying Cars… Sort Of

Joby accelerated its hydrogen power exploration in 2022 by acquiring hydrogen-powered aircraft startup H2Fly, which completed the first piloted flight of a liquid hydrogen-powered electric aircraft last year. Since then, two other California startups have tested hydrogen fuel for propeller planes, with Universal Hydrogen reportedly flying at altitudes up to 10,000 feet and speeds around 170 knots (195 mph). Joby’s test flight, however, marks the first reported instance of a VTOL aircraft completing a test flight using hydrogen power.

“Traveling by air is central to human progress, but we need to find ways to make it cleaner,” Joby CEO JoeBen Bevirt said in a press release. “With our battery-electric air taxi set to fundamentally change the way we move around cities, we’re excited to now be building a technology stack that could redefine regional travel using hydrogen-electric aircraft.”

Hydrogen power has the potential to extend the range of VTOLs, making regional travel between cities more feasible. Joby envisions a future where hydrogen VTOLs could transport commuters between cities like Baltimore and Boston or Nashville and New Orleans. These hydrogen-powered aircraft could utilize much of the same infrastructure currently being built for electric models.

Despite the promising environmental benefits, hydrogen power remains significantly more expensive to produce than its electric or fossil fuel counterparts. Nonetheless, proponents believe it could help reduce CO2 emissions in the transportation sector. Aircraft accounted for around 2% of global CO2 emissions in 2022, according to the International Energy Agency, and this percentage is expected to rise as air travel rebounds from the Covid-19 pandemic.

In summary, hydrogen power could reduce emissions and extend the range of VTOLs, presenting a promising future for cleaner regional air travel. However, the high production costs of hydrogen fuel continue to pose a significant challenge.