Sunbeam-Powered Portable Factory

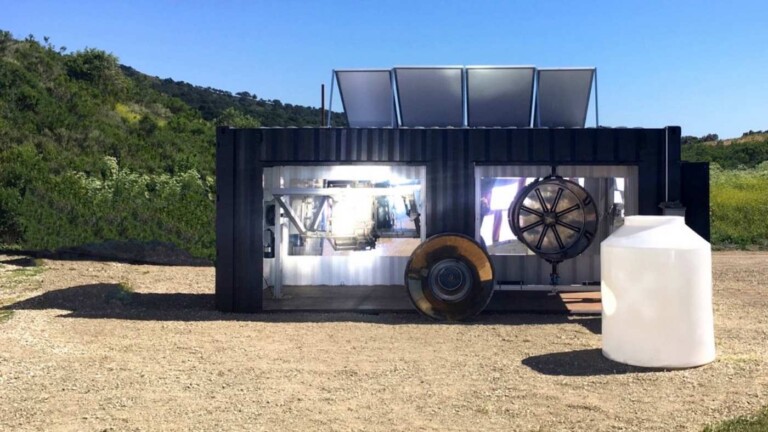

A startup has developed a portable factory that uses solar energy to produce high-quality plastic products such as water tanks and boat frames. This factory, which can be transported globally via shipping containers, offers speed and flexibility, making it ideal for various applications from disaster relief to rural development.

The technology, called Solar Rotational Molding (SRM), involves placing raw plastic in a mold and heating it with concentrated sunlight using 30 heliostats. These mirrors adjust automatically to follow the sun, ensuring continuous exposure.

Karl von Kries, the founder of Light Manufacturing and inventor of SRM, started his entrepreneurial journey after noticing high energy costs at a Massachusetts-based company where he previously worked. Inspired by the potential of solar heat, he established Light Manufacturing to explore solar rotational molding, despite initial skepticism about its feasibility.

To his surprise, the solar molding process proved successful. By 2014, the company was producing high-quality plastic parts and had secured several patents. Von Kries sees SRM as a valuable tool for providing essential infrastructure in rural areas of developing countries, such as pipes and rainwater tanks.

The SRM system, housed in a shipping container, includes a rotational axis, control panels, and electrical components, requiring only an acre of flat land for setup. This setup is significantly cheaper than traditional molding systems, costing one-tenth as much. With minimal operating costs and a two-person crew, the system produces finished products at 20-30% lower costs than conventional methods.

Light Manufacturing has already deployed a system in Hawaii, demonstrating the practical application of their technology.