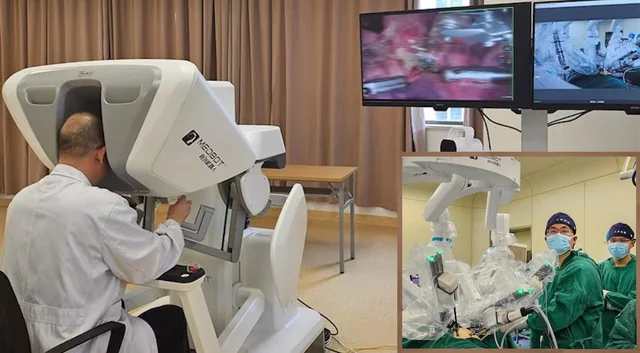

Long Distance Surgery

Dr. Luo Qingquan has pioneered a groundbreaking approach in telesurgery by using a control center to operate robotic tools and remove a lung tumor from a patient located 3,000 miles away. Dr. Luo, stationed at Shanghai Chest Hospital on China’s Pacific Coast, guided the surgery for a patient at a hospital in Kashgar, Xinjiang Autonomous Region.

This innovative procedure was made possible by the Chinese-made 5G Medbot, which enabled Dr. Luo to apply his precision and decades of experience across three time zones in real-time. This advancement marks a new era in telesurgery, potentially transforming healthcare access in rural areas where the shortage of expert medical professionals previously meant limited or no treatment options.

Shanghai Chest Hospital, renowned as the first facility in China to offer robot-assisted surgeries and the leader in such procedures nationwide, demonstrates the potential of this technology.

Globally, the scarcity of specialist surgeons significantly hampers medical progress, especially in low- and middle-income countries. With only about 1.1 million surgeons worldwide and half as many anesthesiologists, even high-income nations face shortages. According to a Lancet review, low- and middle-income countries have only 0.7 specialist surgeons per 100,000 people, compared to 5.5 in high-income countries. Consequently, 48% of the global population relies on just 20% of the world’s surgical workforce.