Wind Turbine ‘Virtual Factory’

Offshore wind turbine maintenance is about to improve with the new ‘Jack-up on Jack-up’ concept introduced by Danish naval engineering firm Knud E Hansen. This design creates a “virtual factory” around turbine blades, allowing technicians to work continuously, regardless of weather.

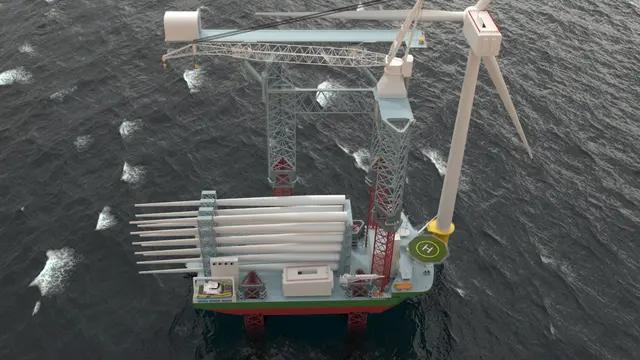

If successful, this concept could greatly enhance the efficiency and reliability of offshore turbine maintenance, pushing the industry towards more operational stability. The design centers around a four-legged platform with a 49.2-foot-wide (15-meter) work area that can be raised to the height of the nacelle (the housing at the top of the turbine). It also features a telescopic weather cover, which provides a controlled environment for technicians to work on blades in almost any weather, day or night.

Knud E Hansen highlights this as a key benefit, noting that traditional methods, reliant on favorable weather for vessel and rope access, often face delays. This new platform allows for a more dependable maintenance schedule, reducing turbine downtime and enabling continuous power production.

A standout feature of the ‘Jack-up on Jack-up’ design is its onboard workshop—a large, air-conditioned workspace at the platform’s rear. This allows technicians to perform complex repairs on-site, eliminating the need to transport damaged blades to shore. The platform also includes a “cherry picker” for easy access to the nacelle, streamlining repairs and reducing logistical challenges. It is designed to handle even the largest turbines, up to 20 megawatts, and operate in water depths of up to 262 feet (80 meters).

Capable of maintaining blades up to 426 feet (130 meters) long and replacing nacelles weighing up to 1,000 tons, this platform is built to meet the demands of current and future offshore turbines.